YONGXIN tin can machine are great containers to seal different foods and beverages. Ever thought about the interesting process of how these pieces use to be created? It's truly quite intriguing! Well, it falls under the answer to what exactly is tin can making so here we're going to go deeper into this world of how ever fascinating portion in unraveling.

Although today, YONGXIN steel sheets are predominantly used to produce tin cans. The first thing to do in the tin can production line is exact cutting of steel sheets into necessary size for a future tin. Those sheets are further coated with a thin layer of tin coat closely adhered before getting cut into sizes This specific coating plays a vital function in protecting the can from corrosion while enabling an imperceptible seal

After this stage of automatic can steamer, the steel sheets are skillfully molded into a can shape. This elaborate shaping process is carried out by a highly specialized machine that skillfully pushes the sheet into its desired can shape. The top and bottom portions are now meticulously attached to the centre body of the can, - creating a strong durable make.

Here are the main stages of creating YONGXIN tin cans. First, all steel sheets are cleaned and coated with a base layer of tin through a process called tinning. Important tinning, because without it there is no chance to be able to seal the can or protect its steel from rust

The rolls are now cut to precisely the size and shape needed for making cans. Then these lock steamer machine are sent through a specialized forming machine that creates the unique shape of cans. Here the top and bottom components are bonded separately in to body of can which give us a full functional form.

YONGXIN Tin cans are simply amazing in how versatile they can be. They make perfect packaging vessels for food, beverages and many other items. Their durable build and sturdiness ensures a long-lasting product, which means these are perfect for storing items that require to be stored for longer times

Further, Automatic can steamer machine are highly customizable and can be made to look absolutely stylish. A lot of companies want to improve the looks by adding colourful labels and designs, which will make them beautiful when sold on stores. This smart manner of working not just attracts the consumers, but to a great extent adds charm to their overall product.

To fucking summarize.. the production of YONGXIN tin cans is damned fascinating with a steps. Every step, from cleaning and coating steel sheets to forming the necessary shapes of cans is essential for ensuring their proper functionality

Like gold, double steamer machine also serve as valuable containers for a variety of goods. And for companies that are looking to woo customers with aesthetically driven packaging, the fact that glass bottles can be visually improved upon further make them an appealing option.

JIUJIANGYONGXINCAN CO. LTD are accredited with SGS, CE and other certifications for our tin can making process, as well as for our automatic round and square can bodies. We also have more than 84 patents including for automated small rectangular can body machines, for automatic round and rectangular can seaming machines as well as an automated paper can seaming machine and others, which are protected by the independent intellectual property rights. It was recognized as a technologically advanced enterprise in the province of JIANGXI Province, China.

We have a skilled team who can provide after-sales support to tin can making process our machines in a proper way.

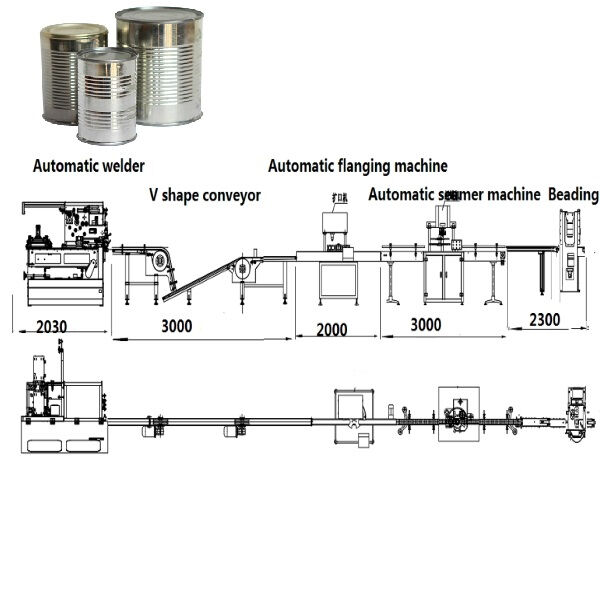

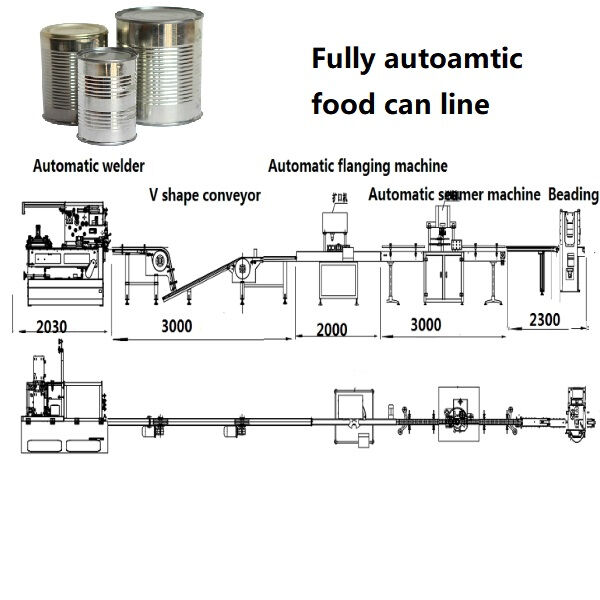

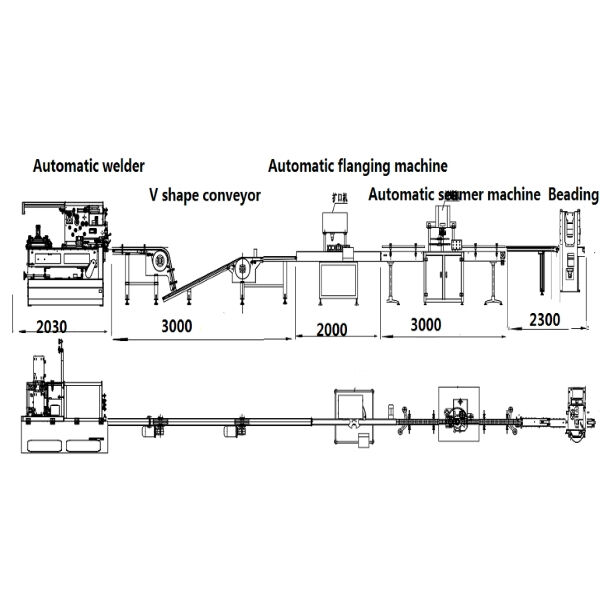

Since 2005, Jiujiang Yongxin Can Equipment Co., Ltd has been tin can making process and production of tin can equipment. We have high-speed automated equipment, like the general small round 40/60cpm can line; 30/50cpm rectangle small can line; 30cpm pail can machine line and 30cpm square big can line. Our products are shipped not just to the local market, but additionally to India, Vietnam Indonesia, Thailand Dubai, Jordan, Saudi Arabia Greece, Kenya South Africa and many other countries. We are a manufacturer of original products with a wealth of experience. We offer cutting-edge technology, high-quality can machines as well as excellent after-sales service. We, Jiujiang Yongxin can equipment Co., Ltd will be your best choice for making cans with our machines.

Jiujiang Yongxin Can Equipment tin can making process that have more than 20 years of experience in the can manufacturing industry. Provide all kinds of can making machines in semi-automatic and automated versions. High-quality and top service. Can sizes vary from 0.1L-25L in round and square cans for food, paint and general use. With good after sales service and reliable running conditions, Yongxin Can making machine has enjoyed a favorable reputation among can makers. With years of study we've developed the automatic UN Pail line. Closed drum making line. Visit our website for more details on making cans.

Our professional sales team are waiting for your consultation.