تصبح هذه الآلات ضرورة لجميع شركات علب الصلب. هذا يجعلها تنمو أسرع من معظم الشركات الأخرى التي تعمل في نفس مجال الأعمال. إذا كانت الشركة تمتلك هذه الآلات الجديدة، ستتمكن من إنتاج علب الصلب بشكل أسرع وبجودة جيدة. وفي ظل سعي العميل للحصول على أفضل المنتجات الممكنة خاصةً في سوق تنافسي، فإن هذا أمر حيوي. يمكن للشركات الاستفادة من هذه الآلات لضمان أن منتجاتهم تكون دائمًا جيدة وموثوقة. لذلك، فإنكم تعلمون أن العلب التي تصل إلى المستهلكين تحتفظ بموادهم الغذائية و/أو المشروبات.

يقوم مصنعو آلات صناعة علب الصلب ببذل جهد إضافي لإنتاج هذه العلب ذات الجودة العالية. وعلى خط الإنتاج، يجب أن تكون العلب المعدنية الخارجة من الخط ذات جودة عالية جدًا. وهذا مهم أيضًا لأن العلب مصممة لتكون صالحة للاستخدام، أي أنها وعاء آمن ومناسب للأغذية والمشروبات. إنها آلات تم تصميمها وبناؤها لتلبية تلك المواصفات الحيوية. من الضروري للغاية التأكد من أن كل علبة تنتجها هذه الآلة تخرج بشكل مثالي، منذ بداية تصنيع العلب حتى النهاية.

لا تكتفي هذه الآلات بتصنيع العلب فقط، بل إنها أيضًا سهلة الاستخدام. وهذا يجعل العمال قادرين على تشغيل آلاتهم بسلاسة لإنتاج ما هو مطلوب. البساطة هي الطريق الأمثل بالنسبة للآلات - فهي أسهل وأكثر أمانًا ويمكن للعمال العمل بشكل أفضل. يؤدي ذلك إلى منتجات أفضل، لأن العمال سيقللون من الأخطاء عندما يكونون قادرين على التعامل مع الآلات بسهولة أكبر.

التكنولوجيا الجديدة في آلات علب الصلب ضرورية للحصول على إنتاج ذي جودة عالية. هذه التكنولوجيا تضمن أن علب الصلب تكون في حالة ممتازة. هذه الآلات أفضل من الأنواع القديمة التي لا تمتلك مثل هذه الميزات والقدرات المتنوعة. باستخدام أفضل وأحدث التكنولوجيا لصنع علب الصلب ذات الأبعاد المناسبة، يتم تصنيع منتجات ذات جودة عاليةSizePolicyBasedTinCan_paymentColumnsMode

وبالتالي، تقدم شركات تصنيع آلات علب السمن وحدات مخصصة لعملاء مختلفين. وهذا يسمح بتعديل الآلات وتكييفها لإنتاج أشكال دقيقة، وخواص مواد وأحجام قد يحتاجها العميل. وهذا يقدم خيارات أكثر للعملاء ويمكن أن يؤدي إلى حلول أكثر ملاءمة لتلبية احتياجاتهم بنجاح. يمكن أن تكون الفريدة من نوعها جاذبة لعملاء أفضل وأكثر، لذلك فإن التخصيص هو المفتاح الأساسي لذلك.

ستستمر الإنتاج دون توقف بينما تقضي الآلات وقتًا قليلًا جدًا خارج الخدمة. عندما لا تعمل الآلات، يكون ذلك توقفًا فعليًا ويبطئ العملية بشكل فعال. يجب الحفاظ على الآلات في حالة جيدة للعمل بكفاءة مع مرور الوقت. يتضمن هذا الصيانة فحص الآلات لأي أضرار واستبدال أي مكونات قد تسبب الضرر.

أخيرًا، فإن منتجي آلات علب الصلب هم أيضًا لاعبون رئيسيون في دعم تصنيع علب الصلب. من خلال الاستثمار في آلات جديدة، يمكن للشركات مواكبة المنافسة وإنتاج علب عالية الجودة يشتريها العملاء. هذه الشركات المصنعة خاصة بسبب جودة الآلات التي تنتجها وكيف يمكن تعديلها حسب الطلب لتلبية وظائف معينة. إنهم يساعدون في الحفاظ على سلامة عملية الإنتاج ويضمنون أن علبنا آمنة لجميع أنواع الاستخدامات.

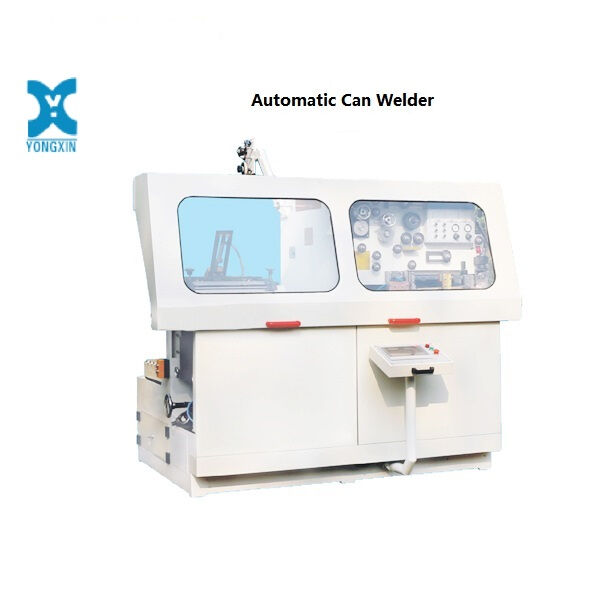

مع أكثر من 20 عامًا من الخبرة في تصنيع آلات صنع علب المعدن، تخصصت شركة Jiujiang Yongxin Can Equipment في آلات صنع العلب. نقدم أنواعًا مختلفة من آلات صنع العلب، سواء شبه آلية أو آلية بالكامل. تتميز هذه الآلات بجودة عالية وخدمة ممتازة. تتراوح أحجام العلب من 0.1 لتر إلى 25 لترًا، وهي متاحة بشكل دائري ومربع لاستخدامات الطلاء والغذاء والاستخدام العام. مع الدعم بعد البيع واستقرار التشغيل، حازت آلة صنع العلب من يونغشين على ثقة مصنعي العلب. وبعد سنوات من البحث في هذا المجال، قمنا بتطوير خط إنتاج أوتوماتيكي للباليه UN. خط إنتاج صناديق مغلقة. افحص موقعنا الإلكتروني لمزيد من التفاصيل حول صنع العلب.

لدينا فريق مدرب يمكنه تقديم خدمات ما بعد البيع لشركات تصنيع آلات صنع علب المعدن لاستخدام آلاتهم بشكل صحيح.

نحن، شركة JIUJIANGYONGXINCAN EQUIPMENT CO. LTD حاصلة على شهادات SGS و CE وغيرها لآلات غلق الأوعية التلقائية الخاصة بنا، والتي تشمل أجسام أوعية مربعة ودائرية. نحن نصنع آلات تصنيع أوعية معدنية، مثل آلات تصنيع أجسام الأوعية الصغيرة التلقائية، وآلات غلق دائرية ومربعة تلقائية وكذلك آلة غلق أوعية ورقية آلية وأخرى، والتي تحميها حقوق الملكية الفكرية المستقلة. وقد تم الاعتراف بالشركة كشركة متقدمة تقنيًا في مقاطعة جيانغشي، الصين.

شركة جيوجانغ يونغشين لصناعة معدات العلب المعدنية المحدودة تعمل في تصنيع وتطوير آلات صنع علب معدنية منذ عام 2005.我们现在 نمتلك آلات أوتوماتيكية عالية السرعة مثل: خط إنتاج العلب الدائرية الصغيرة بسرعات 40/60 علبة في الدقيقة، خط إنتاج العلب المستطيلة الصغيرة بسرعات 30/50 علبة في الدقيقة، خط إنتاج العلب المخروطية بسرعة 30 علبة في الدقيقة، وخط الإنتاج الكبير للمربعات بسرعة 30 علبة في الدقيقة. بالإضافة إلى السوق المحلية، يتم تصدير منتجاتنا إلى الهند، فيتنام، إندونيسيا، تايلاند، دبي، الأردن، السعودية، اليونان، كينيا، جنوب أفريقيا والعديد من الدول الأخرى. باعتبارنا شركة ذات خبرة، نقدم تقنيات حديثة وأجهزة تصنيع علب معدنية راقية مع خدمات ما بعد البيع الممتازة. شركة جيوجانغ يونغشين لصناعة معدات العلب المعدنية المحدودة هي الخيار المثالي لآلات تصنيع العلب.

فريق المبيعات المحترف لدينا في انتظار استشارتك.