Jerry can is something of importance that used daily up-to a great extent. Let's face it, even though we are all jerry can critics, have you ever stopped to think how they manufacture a boring colourless 20l water/plastic container? There are multiple steps in the process and it is honestly very interesting. In this blog article, we will discuss the manufacturing process of jerry cans and what it takes to produce them.

A popular style of container, the jerry can has a unique past that dates way back. For the first time, it was introduced for use in World War II to store gas used with military vehicles. Jerry cans provided a way to transport fuel safely for soldiers. Lately, jerry cans are used to store and transport all sorts of liquids by people. You can use containers for water, gasoline, cooking oil and all of the other liquids that are essential to life.

Here is a brief on how the process of making jerry cans happens : This process is initiated by the design of the can and extends all they way to deliveing that product from one store in America, usable at a bar 15 miles away. The objective of the companies is to manufacture a robust, safe product that will be usable for many years. They concentrate on producing a can that is properly constructed and up to spec for the liquids it was designed to hold.

Next, we have to install the holes onto the cans. Welding is a process that enables this. For the process where two bits of metal are bonded together by heat is called welding. In the end, full of gasoline or water, no less. Obviously, if the weld did not bond well enough than it would fail and you have a dangerous can. The weld also has to lay flat or there will be a leak in the metal line (very bad).

Weld the rolled edge of the new can and then clean it up after alluddle. The cleaning process is very important because any dirt or grime can inhibit the ability for them to hold liquid properly. After the cleaning, a primer is applied to an empty and clean can. Paint also has two uses: it protects the metal from rust and corrosion, which can eventually become weak and dent inwards, but paint makes them look pretty with great colors.

After the can is filled and has undergone either heat processing or sterilization, it ships off for packing then on to grocery stores around the globe. After that the cans have to be packed for sale. Proper Packaging - Since these are tin cans, they could not be easily transportable without a real package. Companies want to make sure that when their cans are coming in the stores, they reach all perfectly okay and safe for consumers.

This implies the preferable capacity of the ought to be water/air proof yet that will have enough quality to manage the weight from inside so it won't break or spill. Safety Requirements for Companies that Manufacture Jerry Cans That includes ensuring the cans are properly marked so people know what is inside and how to treat it safely. This company should also enforce rules for their worker to prevent any incidents or accidents inside the workplace

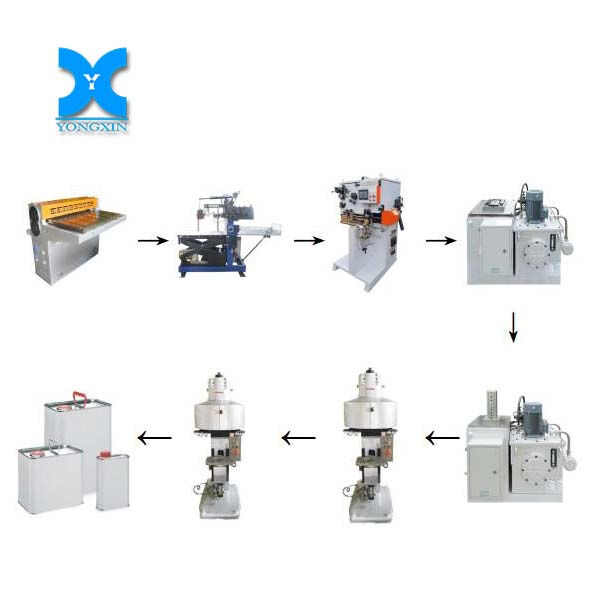

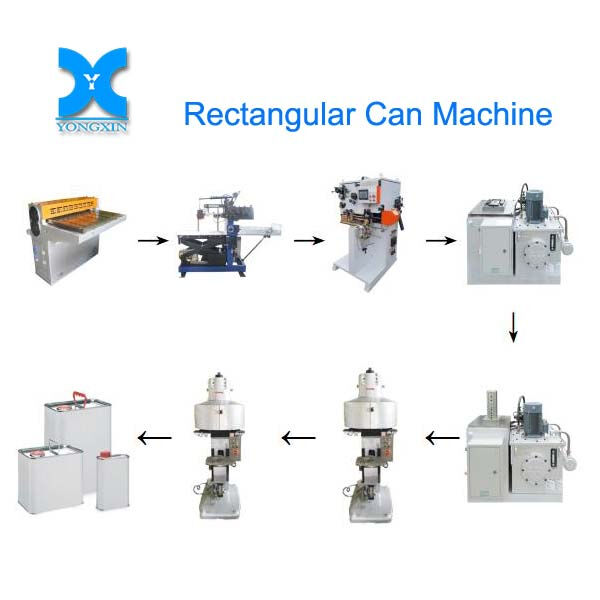

We are JIUJIANGYONGXIN CAN EQUIPMENT CO., LTD and is jerry can manufacturing process, SGS testing and other certifications, for the products of the automatic can seaming machine, automatic round and square can body making machines. We also have the benefit of 84 patents on products like automatic small rectangular can bodies that are automatic round and rectangle can seaming machines, automated machine for seaming paper cans and more. They are protected by independently owned intellectual property rights. The company was recognized as a technologically advanced enterprise in the province of JIANGXI Province, China.

Jiujiang Yongxin Can Equipment jerry can manufacturing process that have more than 20 years of experience in the can manufacturing industry. Provide all kinds of can making machines in semi-automatic and automated versions. High-quality and top service. Can sizes vary from 0.1L-25L in round and square cans for food, paint and general use. With good after sales service and reliable running conditions, Yongxin Can making machine has enjoyed a favorable reputation among can makers. With years of study we've developed the automatic UN Pail line. Closed drum making line. Visit our website for more details on making cans.

Since 2005, Jiujiang Yongxin Can Equipment Co., Ltd is devoted to the research and development of tin can equipment. We have high-speed automatic machines, such as the jerry can manufacturing process; 30/50cpm square small can line; 30cpm pail can machine line, and a 30cpm big can lines that are square. In addition to the domestic market, our products are also exported to India, Vietnam, Indonesia, Thailand, Dubai, Jordan, Saudi Arabia, Greece, Kenya, South Africa, and more. We are a pioneer manufacturer with a wealth of experiences. We offer the latest technology, top quality can machines as well as excellent after-sales service. We at Jiujiang Yongxin can equipment Co., Ltd will be your best choice for can making machines.

We have a skilled team who can provide after-sales support to jerry can manufacturing process our machines in a proper way.

Our professional sales team are waiting for your consultation.