Tin machinery is a machine that contains tin metaled And under this Can be e.g. as part of marine equipment / sea transport queue Tin is a bluish-white, light soft metal and it can be used in various fields for different purposes. An array of items are made from tin machinery, right form household products to industrial machines. This blog is a step by step guide on the versatility of tin machinery & its application in various industries.

From there on out fungible tins machinery has developed very far. Tin was essentially used as a structural material, and previously tin machinery mainly includes household products such as cast iron cans, cutlery or containers. However, with the advancement of technology tin machinery has also evolved and is used in various industries today. From basic household items, tin as a machinery has come a long way to take different forms of complex industrial machines while strongly adapting in each field.

Tin machinery does not become what it is overnight, instead; Tin engineering grew through an elaborate process. To make it a reality, however, requires meticulous research and design with rigorous testing. This in turn always means that producers of tinsmithing machines should consider carefully what the buyer needs and develop a machine, which does not only satisfy but rather overperforms the need. Development of an initial idea into a fully functional TIN machine includes several stages to make the system efficient and effective for real-world use cases.

The durability of tin machinery is one of its biggest selling points. An extremely robust metal, strong and resiliant in less than ideal conditions tave it very sturdy properties which are friendly to preservation. In addition, tin is enormously corrosion and rust resistant which makes it a candidate for working in calls of severe environments where machines are operating. Similarly, the hassle-free nature of tin machinery enhances its appeal to businesses- it basically means that they are able be cost-effective and work-improving.

Tin machinery of course works on the basis of producing and manufacturing. The phenomenon helps businesses to optimize their processes, increase efficiency and productivity as well as maintaining superior quality of goods. Most of the above mentioned industries used tin machinery for their day to day operation like food processing, packaging and many others. Certainly, the requirements of modern production standards would prove difficult for these industries to meet without the input from tin machinery.

In summary, Tin machinery is perfect in most of the industry with its' a high utility equipment platform. This also helps companies to capitalize on a maintenance-light routine, thanks to the incredible endurance and corrosion resistance of stainless steel. The evolution of tin machinery represents the ongoing development and flexibility within the manufacturing industry, highlighting its importance in achieving efficiency and quality throughout contemporary production methods.

We have a tin machinery that offers after-sales service to assist customers in maintaining and utilize our machines in a proper way.

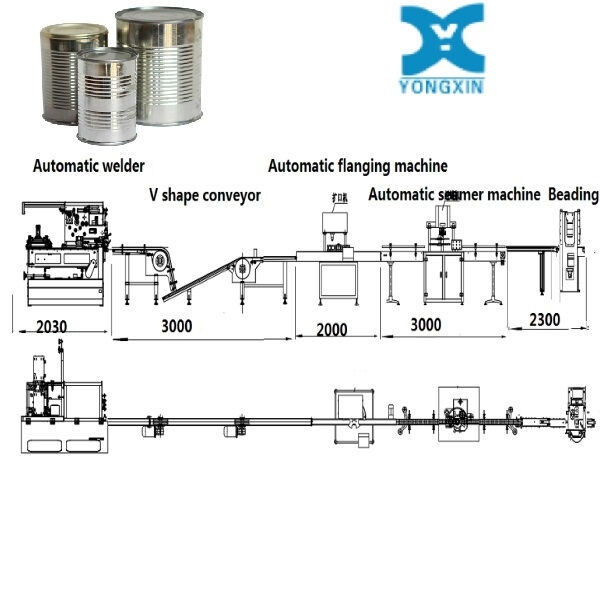

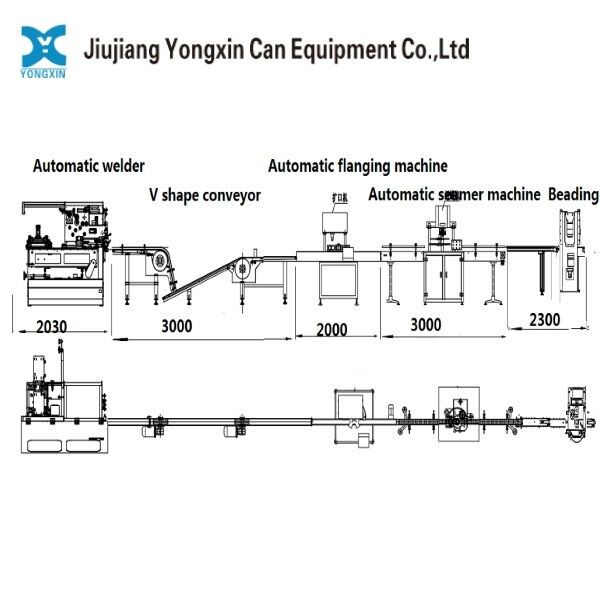

With tin machinery in can manufacturing, Jiujiang Yongxin Can Equipment specializes in making cans with machines. We offer all types of can-making machine both semiautomatic and automated. with the highest quality and service. Can sizes are 0.1L-25L for square and round cans. These cans are utilized in paint, food, and general purpose. Yongxin can making machine is recognized by can makers as a reliable and high-quality can maker. Check out our website for more information about can making.

Since 2005, Jiujiang Yongxin Can Equipment Co., Ltd is tin machinery and manufacturing of Tin Can Machinery. We have high-speed automatic machines, such as the 40/60cpm general small circular can line; 30/50cpm rectangle small can line; 30cpm pail can machine line, and a 30cpm square big can line. Our products are not only exported only to the domestic market but as well to India, Vietnam Indonesia, Thailand Dubai, Jordan, Saudi Arabia Greece, Kenya South Africa and many other countries. As a pioneer manufacturer, we supply advanced technology high-end can machinery and excellent after-sales services. Choose Jiujiang Yongxin Can Equipment Co., Ltd for your can-making machines.

We, JIUJIANGYONGXINCAN EQUIPMENT CO. LTD is tin machinery, CE and other certifications for our can seaming machines, as well as for our automatic round and square can bodies. We also hold Patents 84 for various products like small, automatic can bodies that are automatic round and rectangle can seaming machinery, automatic paper can seaming equipment and other. They are protected by independently owned intellectual property rights. The company was categorized as a "high technological enterprise in the province of JIANGXI Province" in China.

Our professional sales team are waiting for your consultation.