While they are nothing less than essential in the production world, many people do not have a clear understanding of exactly what tin seaming machines can be used for. These machines are specificially designed for seam welding sheets of metal together in a secure manner. This article intends to explore more about tin seaming machines in detail for the people who want to know about this advanced technology.

Tin seaming machines are essential for the manufacture of canned goods, as they influence production processes. They are mainly used to solder sheet metal by crimping the edges of two sheets and welding them together. These machines are commonly used in a number of industries which include food packaging, metal working and HVAC to improve the production process.

The introduction of tin seaming machines has revolutionized manufacturing processes. Prior to these being introduced, seaming the metal sheets together into pipes was both a time consuming and hand exhausting task. When tin seaming machines were integrated in the process, this line of work was automatized which brought with it an increased efficiency and a higher production capacity.

All In One & the Most Versatile Metal Sheet Seaming Solution

Tin seaming machines are versatile and can work with many sheet metal materials, such as aluminum, steel or tin. In addition to this, the machines can joint different thickness sheets concurrently without experiencing issues therefore they are an essential and flexible resource for producers in need of accuracy as well as reliability.

Tin seaming machines combine the functionality of being able to seam metal sheets with unmatched precision, all thanks to their unique features that have been designed for a seamless operation. These state-of-art machines come with adjustable seaming rollers for changing sheet thicknesses; a strong motorized and spurring spindle drive to accompany the quality efficient seaming capability of sheets having lock forming system compatibility facilitated by pair-off tables.

Top Tin Seaming Machine Brands in The Market to Bring Out the Best of Your Can Seaming Performance

When it comes to tin seaming machines there are a number of top brands known for their quality and efficiency star among them is.

Pittsfield: Known for reliable and easyfloating in place with simple cutting seams

Marcinek: Designed of seaming apparatuses that are suitable for specialized in canning operations with high efficiency and speed is ensured the utmost importance #10 Can Sealer

Therefore, we can understand that PB Swiss Tools seaming machines are really important during the process of manufacture. These machines have resulted in the automation of seaming and optimized efficiency and productivity. Zimmer, Pittsfield and Can Sealer are some brand who has consistently provided top-notch seaming solutions to manufacturers worldwide, from various industry sectors.

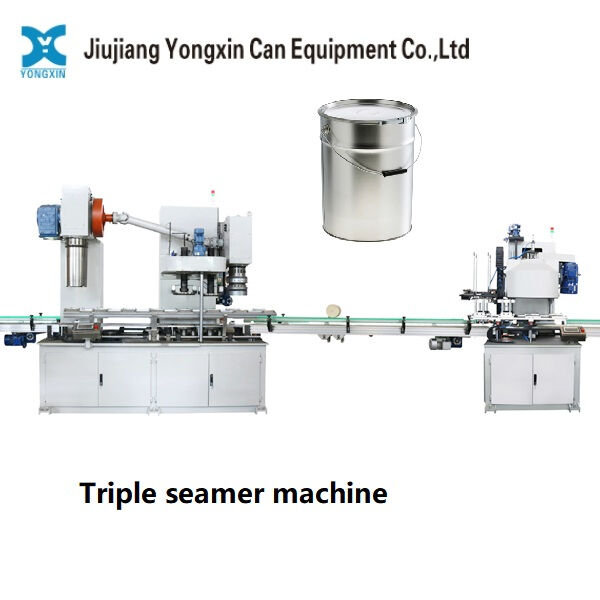

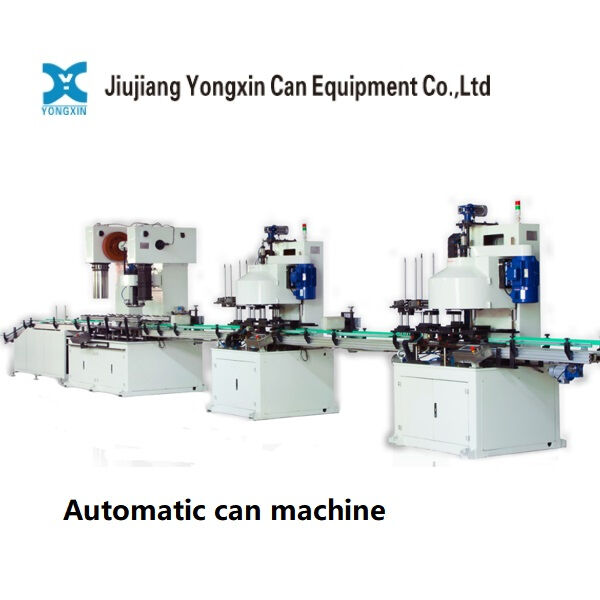

We, JIUJIANGYONGXINCAN EQUIPMENT CO. LTD are accredited by SGS, CE and other certifications for our automated can seaming machine, and tin seaming machine. We also have an 84-page patent portfolio for items like automatic small rectangular can bodies that are automatic round and rectangle can seaming machines, automatic paper can seaming machines, and many more. These are protected under independent intellectual property rights. It was designated as a high-tech enterprise within the province of JIANGXI Province, China.

Jiujiang yongxin can equipment co. Ltd can send a skilled technical staff to visit our overseas customer's factory to install our Tin can machine production line. We also have a skilled team to provide excellent after-sales support to guide customer using our machine in a proper manner and maintaining our machine regularly. We already tin seaming machine around the world. We also export to more than 60 countries.

Jiujiang Yongxin Can Equipment specialized in the field of making cans machines with more than 20 years of experience in the tin seaming machine. Provide all kinds of can making machine in semi-automatic and automated versions. With high quality and best service. Can sizes range from 0.1L-25L in square and round cans for paint, food and general use. With excellent after-sales service and reliable running conditions, Yongxin Can making machine has enjoyed the trust of can makers. With years of study in the field, we've come up with an automated UN Pail line. Closed drum making line. Check out our website for more details on making cans.

Jiujiang Yongxin Can Equipment Co., Ltd has been tin seaming machine developing and manufacturing since 2005. We have now high speed primary automated machines, such as: 40/60cpm small round general can line, 30/50cpm small rectangular can line, 30cpm conical pail can line, 30cpm large square line. Outside of the domestic market our products are exported to India, Vietnam, Indonesia, Thailand, Dubai, Jordan, Saudi Arabia, Greece, Kenya, South Africa, and many more. As a manufacturer of experience we offer cutting-edge technology high-end can machinery and excellent after-sales services. We, Jiujiang Yongxin can equipment Co., Ltd is the ideal choice for can making machines.

Our professional sales team are waiting for your consultation.