Product

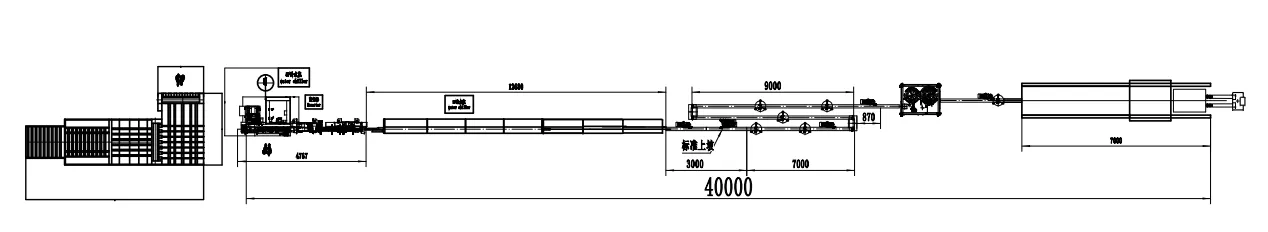

Autoamatic food can line

Product Details

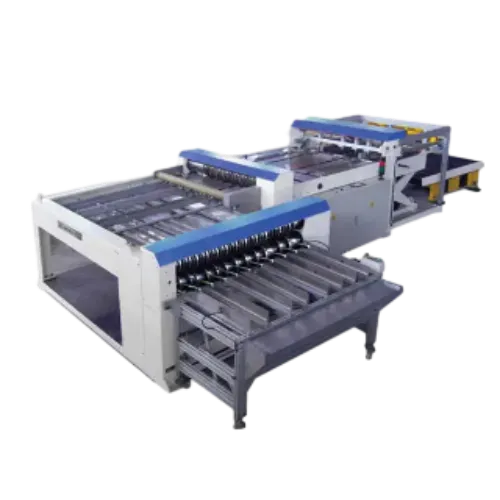

Fully automatic food can line .Including automatic duplex slitter,Can body welder, Insider&outside coating with high frequency induction oven, can body forming machine .Leakage tester. Used for make the food sardine tomato paste can making with speed range 200-400cpm.  1. Automatic Duplex slitter

1. Automatic Duplex slitter

For can-making company to produce the blanks for the can body.

with Mitsubishi electric control components. YUKEN hydraulic components.

The first cutting knives is belong to carbide alloy.

|

Model | GT10CA |

| Max feeding Size | 1200x1200mm | |

| Min Feeding Size | 600x600mm | |

| Slitting thickness | 0.12-0.5mm | |

| Slitting speed : | 32SPM | |

| Diagonal tolerance | ≤0.05mm | |

| Max 1st Slitting qt | 6strips | |

| Max 2nd SlittingQt | 12strips (75-1200mm) | |

| Power | 12KW |

2. Automatic seam welder

|

Modle | FHZ-300 |

| Production capacity | 200-300< cpm | |

| Can diameter | 52-99mm | |

| Can height | 39-120mm | |

| Line speed | 30-50m/min | |

| Weldering frequency | 300-700Hz | |

| Copper wire | 1.27-1.38mm | |

| Raw materials | Tinplate |

3. Rear Feeding Seaming Welding Machine

|

Model: | LS-B5 |

| Cool capacity: | 8500/33745KCAL/BTV | |

| Pump power: | 0.375Kw | |

| Voltage: | 380V/50Hz | |

| Air-pressed power: | 2.25Kw | |

| Tank capacity: | 55LT | |

| Net weight: | 160kgs | |

| Dimension: | 1000x700x1050mm |

4. Inside Outside coating machine

This machine use connecting hanging up conveyor system which is better for powder coating. Model:

|

Model: | GNWT-420 |

| Can diameter | 52-105mm | |

| Coating manner: | Spray way | |

| Coating width: | 10-15mm | |

| Dimension | 1350x800x1800mm | |

| Weight | 450kgs |

5. Induction oven machine

This machine used for dry the can body after lacquering with high frequency induction. Drying capability:

|

Drying capability: | 12-57m/min |

| Model | GTCHG-180 | |

| Drying manner: | High frequency induction curling system | |

| Size of dryer: | 10660x1410x1800mm | |

| Max power consumption | 18kwh | |

| weight | 3000kg |

6. Inside Powder coating machine

This machine take Japan SMC valve,with Mitsubishi PLC and frequency inverter. Model

|

Model | CTPC-2 |

| Conveying speed | 5-60m/min | |

| Coating width | 10-20mm | |

| Can diameter | 52-280mm | |

| Powder type | Polyester | |

| Air compressor | 0.4mpa,0.5m3/min | |

| Motor power | AC220,50HA 2.8KW |

7. Body Flanging beading seaming machine

Vertical design,easy to connect with other machine Recyclable central lubricating system

Multi-safety design for machine and personal safety

Flanging spin rolls are driver by tiny gears receptively Carbide material for machine and personal safety

Can guide and star-wheel with chromium plating

|

Model | GT3B49NFBS |

| Diameter | 52-99mm | |

| Height | 50-160mm | |

| Speed | 200-600mm | |

| Inch | 202-401 | |

| Motor power | 5.5kw | |

| Weight | 5000kg |

8. Automatic Can palletizer

This machine used for palletizer the cans after producing. Model

|

Model | GT3B49NFBS |

| Diameter | 52-99 | |

| Height | 50-160mm | |

| Speed | 300cpm | |

| Inch | 202-401 | |

| Motor power | 3.5kw | |

| Weight | 2000kg |