Product

Product Details

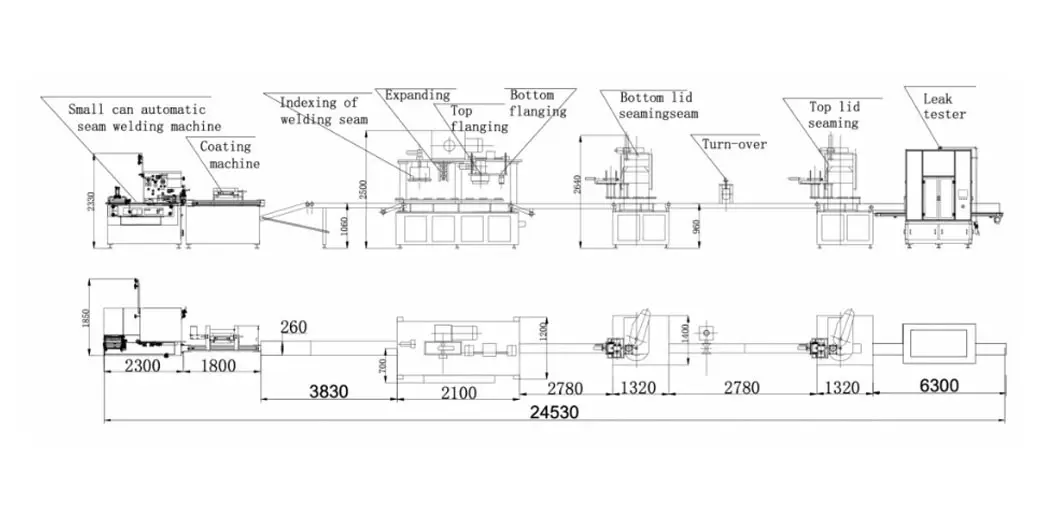

Layout of 1-4L auto rectangular can making machie

1. Automatic Duplex Slitter

|

Model: | GT10A |

| sheet thickness: | 0.12-0.5mm | |

| Max sheet width: | 1200*1200mm | |

| Min sheet width: | 600*600mm | |

| Size error: | ±0.02mm | |

| Diagonal error: | ±0.05mm | |

| Motor power: | 8 kw | |

| Dimension: | 4000x7000x1200mm |

2. Automatic Rolling and Seam Welding Machine

|

Model: | FH18-65ZD |

| Capacity: | 40-60cans/min | |

| Can diameter: | 65-180mm | |

| Can height: | 70-280mm | |

| Applicable material thickness: | 0.18-0.32mm | |

| Applicable copper wire diameter: | 1.38-1.5mm | |

| Cooling water: T:≤20°C P:0.4Mpa Discharge:7L/min | ||

| Power: | 380v±5% 50HZ 18KVA | |

| Dimension: | 1750X1100X1800mm | |

| Net weight : | 1900kg | |

3. Internal & External Coating Machine

|

Model: | GNWT-180S |

| Capacity: | 5-30m/min | |

| Can diameter: | Φ52-Φ180mm | |

| Coating Width : | 8-15mm | |

| Coating type: | Roller coating | |

| Air supply &consumption: | 0.6Mpa 20L/min | |

| Power: | 220V | |

| Dimension: | 2100*720*1520mm |

4. Induction Oven

|

Model: | GDCHG-180-6 |

| Drying way: | Electric induction drying | |

| Working Zone: | 6*800mm | |

| Can diameter: | Φ52-Φ180mm | |

| Conveyor Speed : | 5-30m/min | |

| Weight: | 850kg | |

| Dimension: | 3800*700*1420mm |

5. Automatic Rectangular Can Body Machine

|

Model: | GTYX-S |

| Applicable Can: | 1-4L square can | |

| Capacity: | 25-30 cans/min | |

| Applicable can height: | 100-330mm | |

| Dimension: | 18m(L)*2m(W)*3m(M) | |

| Voltage: | 3-phase 4-wire 380V | |

| Air pressure: | Not lower than 0.6Mpa | |

| Power of whole line: | 40KW |

6.Automatic 1-4L square can leak testing machine

|

Note: | Eight Head precision Leak Tester |

| Capacity: | 1500-1800 pcs/hour | |

| Applicable: | 1-4L square can | |

| Accuracy: | 0.12-0.15mm | |

| Air Source Pressure: | 0.5MPa 500KPa | |

| Testing Air Pressure: | <2 0KPa | |

| Dimension: | 2360*1670*2205mm |