Product

Product Details

It is widely used for 1-5L small round tin can making, such as paint can, glue can, oil can and so on. production capacity is 15-25cans per min. We supplied such line to Saudi Arabia, Dubai, Vietnam, Malaysia, India, Mexico, Jordan and so on.

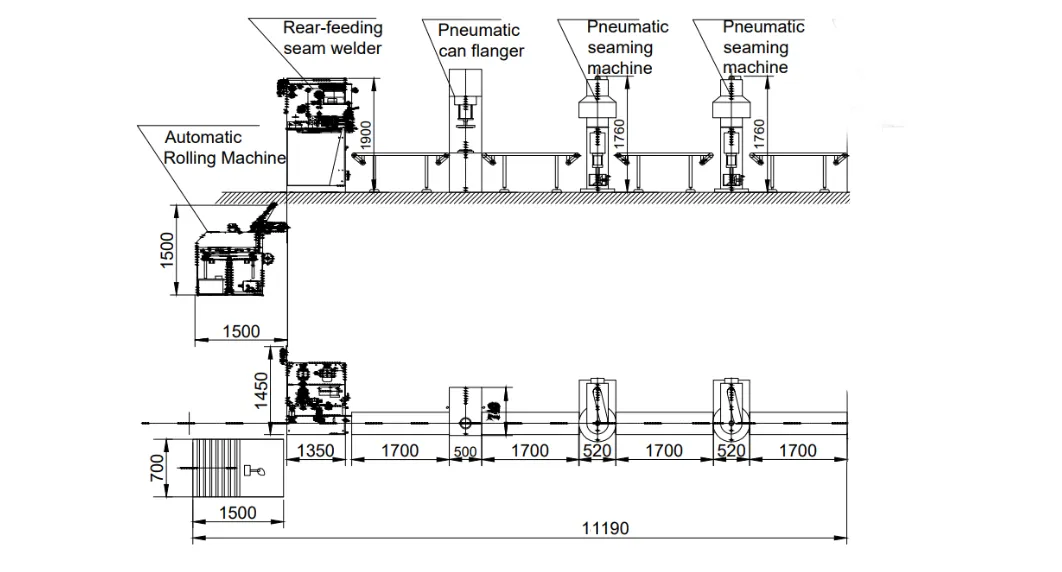

Layout of semi auto round can making line

Machine Details of semi auto round can making line

1. Gang Slitter

|

Model | GT1B5 |

| Max sheet thickness: | 0.4mm | |

| Max sheet width: | 1050mm | |

| Min sheet width | 52mm | |

| Motor power: | 1.1kw | |

| Net weight: | 1400kgs | |

| Dimension: | 1500x1600x1105mm |

2. Automatic Roll forming machine

|

Model | CY400-AT |

| Capacity: | 20-30cans/min | |

| Diameter: | Φ75-Φ300 | |

| Applicative height: | <≤440 | |

| Net weight: | 450kg | |

| Dimension: | 2000×900×1500mm |

3. Rear Feeding Seaming Welding Machine

|

Model: | FB2000-A | FB2000-B | |||

| Power: | 3N380V/50HZ----15KVA | |||||

| Welding speed: | ≤12m/min | |||||

| Capacity: | 20-50cans/min | |||||

| Diameter: | ¢65-300mm | ¢52-170mm | ||||

| Height: | 70-400mm | 70-300mm | ||||

| Overlap: | 0.6-1.2mm | 0.4-1.0mm | ||||

| Thickness: | 0.2-0.4mm | 0.18-0.35mm | ||||

| Copper wire: | ¢1.5-1.7mm | |||||

| Cooling water: | ≥0.3Mpa 8-10L/min | |||||

| Net Weight: | 1300kgs | |||||

| Dimension: | 1350x1300x1700mm | |||||

4. Pneumatic flanging machine

|

Model: | QYA180F |

| Diameter: | 52-180mm | |

| Height: | 50-200mm | |

| Thickness: | 0.18-0.25mm | |

| Capacity: | 15cans/min | |

| Net Weight: | 100kgs | |

| Dimension: | 400x500x1380mm |

5. Automatic ear lug welding machine

|

Power: | 3N380V/50HZ----60KVA |

| Capacity: | 20-25cans/min | |

| Thickness: | 0.2-0.5mm | |

| Compressed air: | 300L/min 0.6Mpa | |

| Net Weight: | 500kgs | |

| Dimension: | 1350×1000×1550mm |

6. Semi auto Pneumatic tin can seamer

|

Model: | GT4A6YQ |

| Capacity: | 20-30cans/min | |

| Diameter: | 50-180mm | |

| Maximum Height: | 300mm | |

| Sheet thickness: | ≤0.4mm | |

| Power: | 1.5kw | |

| Net weight: | 450kgs | |

| Dimension: | 720x520x1760mm |